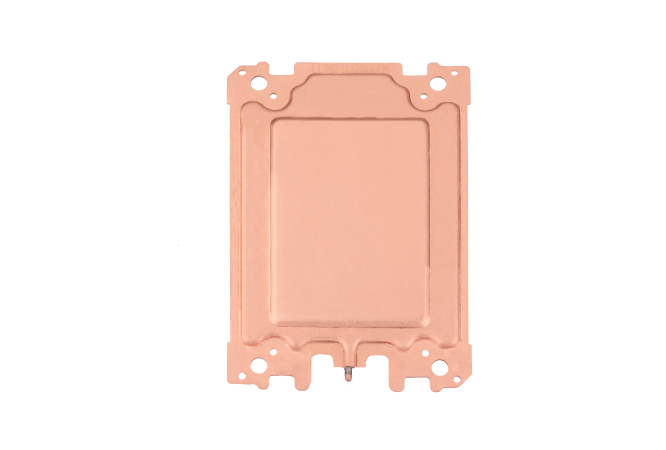

SYNTECS | Complex shaped copper vapour chamber (VC)

SYNTECS will use LST to match and improve the cooling efficiency achieved by sintered wick

VCs (by up to 48%) by enabling enhanced water/vapour transport and evaporation. The

multi-axis SYNTECS machine will enable texturing on internal surfaces of top and bottom

plates which have complex geometries in the X, Y and Z planes.

DLW will be used to produce 50-200 μm grooves on the plates, with aspect ratios (3-5) that

could not be achieved by mechanical methods.

These grooves will support long-range capillary

action to pull water around the system. DLIP (10-20 μm) and LIPSS (100-200 nm)

hierarchical

texturing on top of the grooved structure will promote tangential transport of water

between

the grooves and give a larger surface area for evaporation.

The use of USP burst mode will be used to enhance ablation efficiency (to >5 μm3/μJ, 10x

enhancement vs single pulse USP processing) to bring the process in line with industrial

expectations for the production of ~5M VCs/ year.